The surface finish of the Gao Jie net stainless steel piping system has a very important role in the safe production of food and drug. Good surface finish can be cleaned, reduce the growth of microorganisms, corrosion, removal of metal impurities and other characteristics. In order to improve the surface quality of stainless steel pipe system, that is to improve the surface morphology and morphology structure, reduce the number of the dielectric layer, common surface treatment methods are as follows:

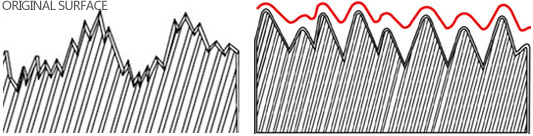

1、Mechanically Polished(MP)

In order to improve the surface roughness, the surface texture can be improved, but the structure, energy level and the number of dielectric layers can not be improved.

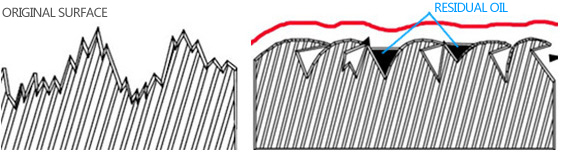

2、Buffed Polished(BP)

Stainless steel industry commonly used to improve the surface brightness of the way, although the Ra value may be very good, but in the electron microscope can observe many cracks, the actual surface area of the expansion, the local separation of the ferrite and martensite structure. Surface inclusion of many impurities and abrasive particles.

Due to the use of polishing paste, many of the non detergent residue is stored in the depression, and gradually released in the fluid, the pollution of food.

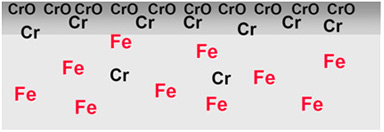

3、Pickled & Passivated / Chemically Polished(AP & CP)

After acid washing or passivation, the pipeline will not improve the surface roughness, but can remove the surface of the particles, reduce the energy level, but will not reduce the number of referrals. In the stainless steel surface to form a protective layer of the passivation of chromium oxide, protect the stainless steel away from corrosion oxidation.

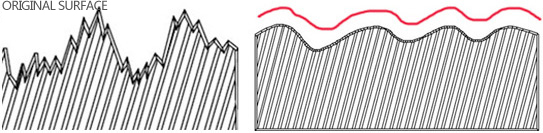

4、Electro Polished(EP)

By means of electrochemical polishing, the surface morphology and structure can be greatly improved, and the surface area can be reduced to a maximum extent. The surface is a closed, thick oxide film, the energy is close to the normal level of the alloy, while the number of medium will be reduced to a minimum.

In order to obtain a perfect result, mechanical polishing is required to be polished.

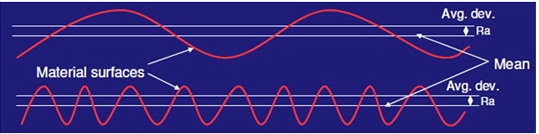

Note that the same Ra values do not represent the same surface treatment

浙公网安备 33039902000184号

浙公网安备 33039902000184号